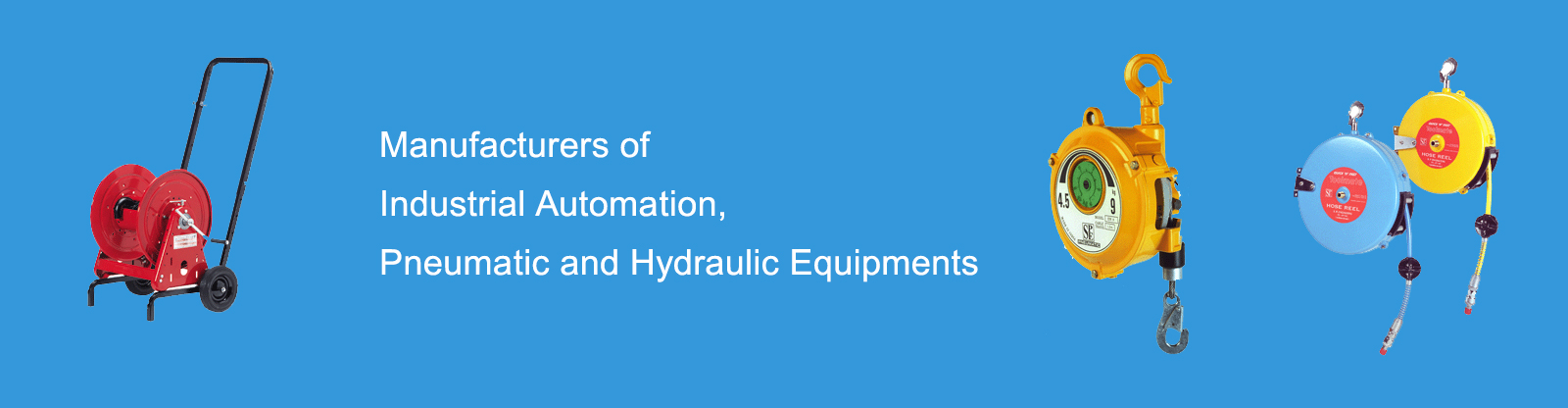

TIPS ON USE OF BALANCERS AND SECONDARY SUPPORT CHAINS

When selecting a balancer, first consideration should be given to the weight of the load to be balanced (tool plus cable or hose plus other attachment). When the total weight has been determined, the balancer model with the proper tension (weight range) can be chosen balancers have an external device for “on-the-job” tension adjustment. The adjustment range for each model is specified in the selection tables. For maximum operator efficiency and balancer life, the tool balancer should always be mounted directly over the work area, with vertical axis perpendicular to the floor when in use. Working with the load not perpendicular causes operator fatigue and excessive wear on balancer cable and drum. When it is necessary to continuously move the balancer and tool from one position to another, a system of trolley and runways can be used. Contact us for choice of trolleys and runways available.

Cable travel is the total length of cable which can be installed on and pulled out of a balancer. Cable overhang is any additional length of cable attached to or part of the active cable, which is not retracted into the balancer. Overhang cable is often necessary for work area with high ceilings. It is strongly recommended that all balancers mounted overhead have a secondary chain attached, to prevent the possibility of the balancer accidentally falling. The chain attaches to the balancer with the other end attached to a support other than the one that supports the balancer. The length of the chain should be kept to an absolute minimum. |

1

1 2

2 3

3